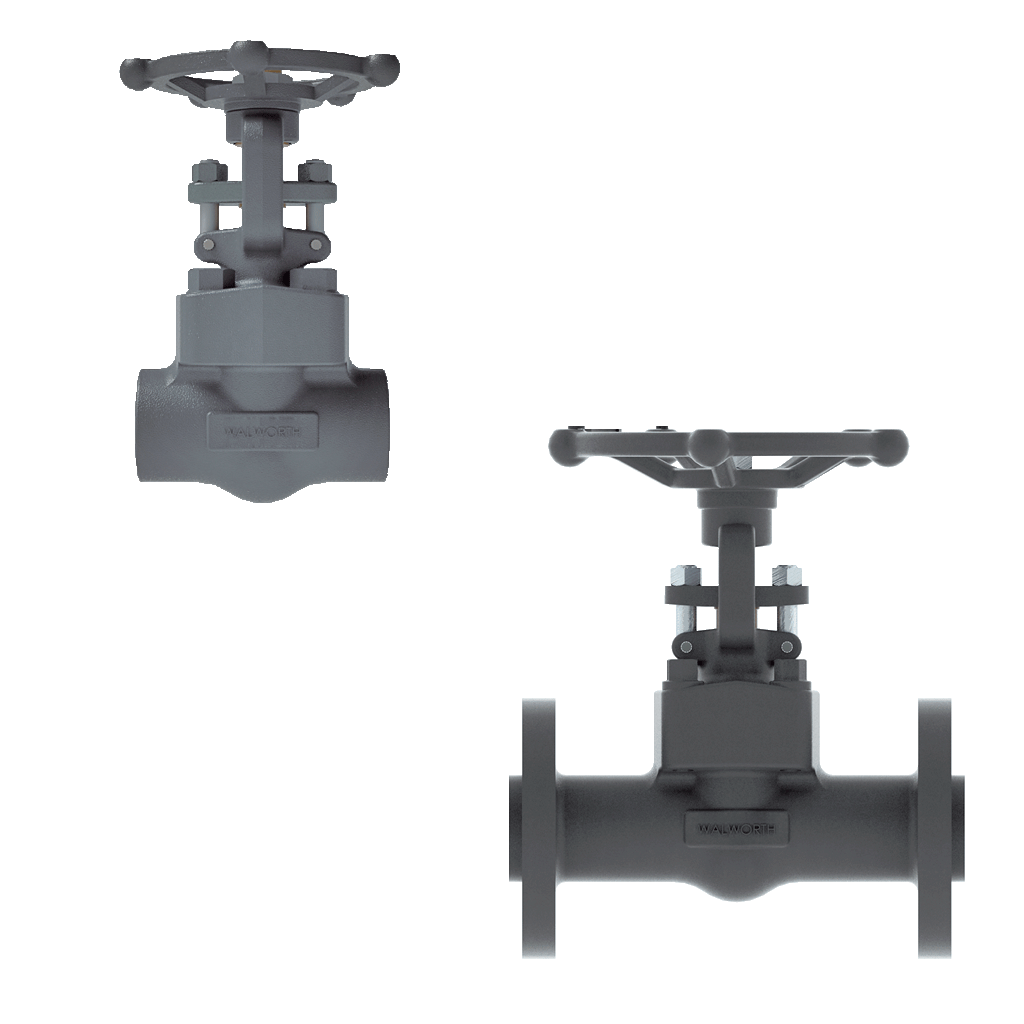

FORGED STEEL GATE VALVES

- This is the compact gate valve design in which components bearing pressure are manufactured from forgings (body and hood). Suitable for installation in refineries, chemical plants, petrochemical plants, oil industry processes or others where corrosion or erosion occurs, or flow diversion is required.

- Designed in accordance with API-602, ISO-15761 and BS-10434.

- -ASME Classes 150, 300, 600, 800, 1500

-Class 2500 as per ASME B16.34. - NPS 1/2 to NPS 2 diameters.

- End types:

-Welding box end (SW).

-Threaded ends (S).

-Integral flanged ends (RF, RTJ). WE ends. Extremos WE.